Regenerative_Turbine_Pumps

Base-mounted_model

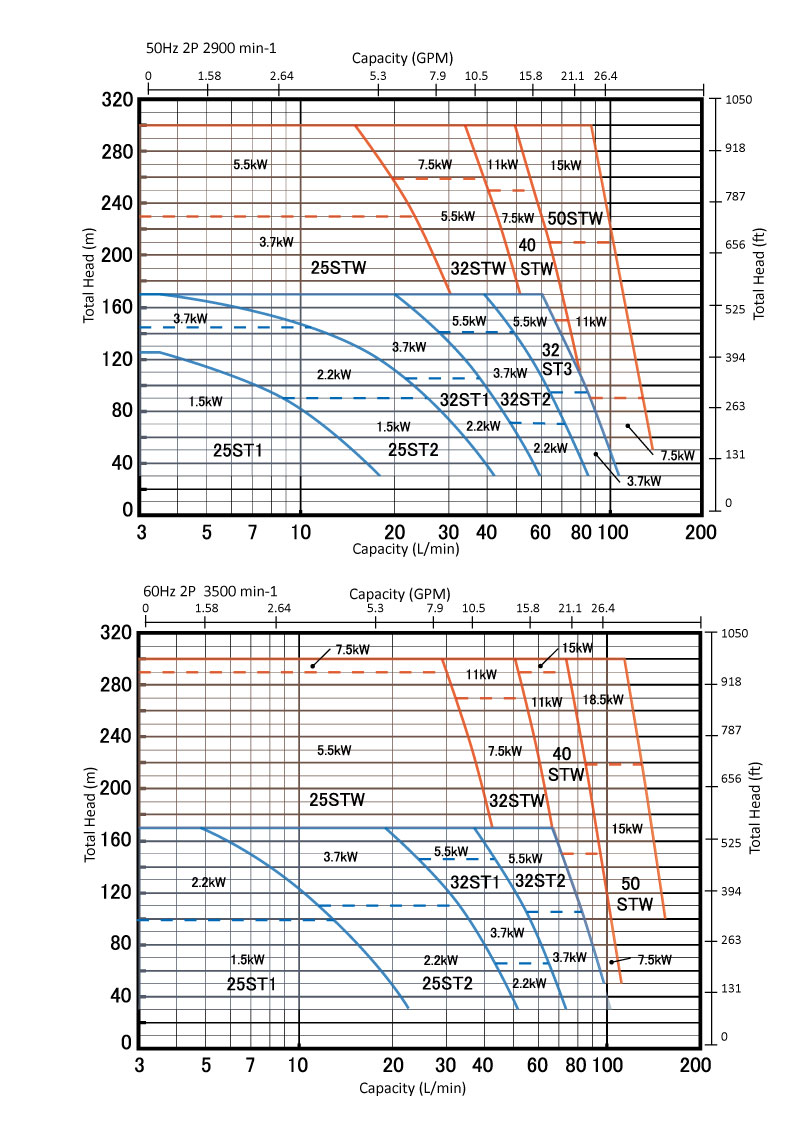

Ferrouos material, super high pressure application (max. 3.0 MPa)

Regenerative_Turbine_Pumps Base-mounted_model Stainless_steel

STW

Applications

General industrial applicationsPure water and chemical liquid supply

Washing solvent supply, suitable for filtration applications

Features

No metal contact between the impeller and the casing and cover, eliminating wear and reducing contaminationSimple robust structure with minimal consumable parts, suitable for processes requiring high reliability.

Due to selection of material combinations (SUS304 / PTFE / SiC) can target variety of applications.

Very low noise levels silimar to centrifugal pumps, additional noise reduction measures not required.

Double-stage impeller structure